先进的喷雾泵设计如何增强香味的应用

香水泵是现代香水包装的重要组成部分,可以高效优雅地喷洒香水,喷洒量小且可控。这些泵旨在将液体香水分散成细雾,确保用户享受均衡一致的香味。香水泵在香水行业的重要性怎么强调都不为过。它们不仅通过确保最佳的香味扩散来增强用户体验,而且还通过限制与空气的接触在保持香水完整性方面发挥着至关重要的作用。

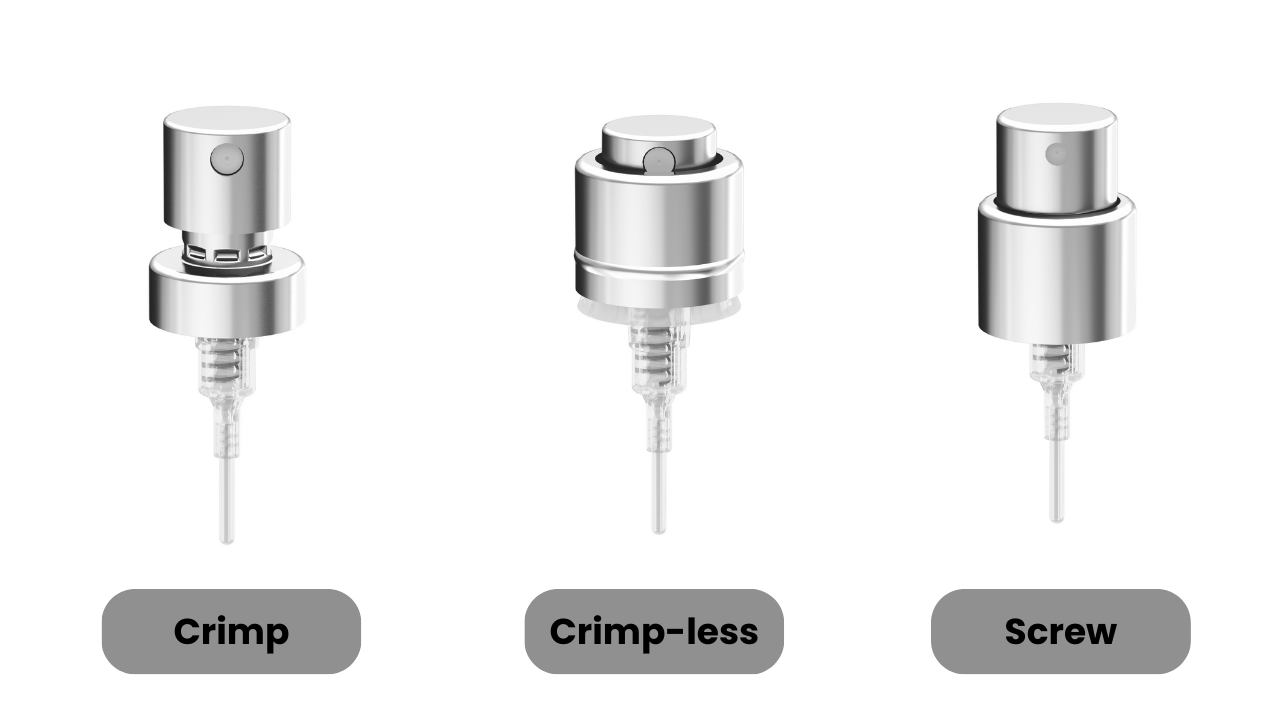

香水泵的类型

香水泵有多种类型,每种类型都有其独特的特点和优势:

● 卷边香水泵: 这些泵通过压接工艺紧密密封在瓶子上,提供牢固的封闭。压接泵通常用于奢侈香水,因为它们提供防篡改包装,确保香水的新鲜度。

● 无褶皱香水泵: 这些泵的设计无需卷边即可安装,从而提供更灵活的包装解决方案。无卷边泵是可再填充包装的理想选择,因为它们可以更轻松地取用内容物进行再填充,而不会影响密封性。

● 螺旋香水泵: 螺旋泵通过螺纹机构固定在瓶子上,便于安装和拆卸。它们通常用于旅行装或可再填充的香水瓶中,因为它们提供了一种方便的方式来在必要时重新填充或更换泵。

香水泵的组件及其工作原理

香水泵的功能基于以下组件,每个组件在整体性能中都发挥着至关重要的作用:

● 喷嘴: 喷嘴是泵的一部分,通过它释放香水。其设计对于实现细雾至关重要,确保香水均匀分布在皮肤上。先进的喷嘴还可以防止堵塞,确保性能始终如一。

● 执行器: 执行器是泵的一部分,用户按下它即可释放香味。它控制从瓶中抽出并转化为喷雾的液体量。高品质的执行器设计用于平稳运行和最小阻力。

● 浸管: 浸管延伸到香水瓶中,按下时将液体吸入执行器。浸管的长度和设计对于确保最大程度地利用产品、最大限度地减少浪费至关重要。

● 关闭机制: 封闭机制将泵固定到香水瓶上,确保密封严密,防止泄漏和蒸发。卷边封闭通常更持久,而螺旋封闭则易于拆卸,适合可再填充的设计。

高品质香水泵的主要特点

高品质香水泵包含几个关键特性,可确保最佳性能:

● 喷雾分散精度: 精心设计的泵可均匀喷洒,将香味均匀地分布在皮肤上。这种精确度可确保香味持续更长时间并更有效地被吸收。

● 喷雾量稳定: 每次按下按钮时,应释放出一致量的香味,为用户提供可靠的体验。不一致的喷雾量会影响用户对香水浓度和持久度的感知。

● 线性扩散技术: 现代香水泵采用线性扩散技术,确保香水以细雾形式均匀分散。该技术可防止大液滴并确保气味清淡清新,从而增强香水体验。

● 最小化喷雾噪音,带来优质体验: 高端香水泵的设计旨在最大限度地减少按压泵时产生的声音。这一微妙的功能增强了产品的奢华感,有助于带来无缝和精致的体验。

香水泵技术的创新

近年来,多项创新改变了香水泵行业,满足了消费者对可持续性、定制化和耐用性的需求。

● 可再填充且可持续使用的泵: 随着环保问题日益重要,香水喷雾器可再填充设计的兴起是一项重大创新。这些泵的设计可重复使用,让消费者可以重新填充香水瓶,而不是丢弃它们。这种方法大大减少了浪费,使其成为香水包装的环保解决方案。可再填充包装概念在寻求可持续替代品的消费者和品牌中都很受欢迎。

● 全塑料材质泵: 作为推动可持续发展的一部分,全塑料材质泵已获得广泛关注。这些泵完全由可回收塑料制成,是一种环保选择,无需使用金属部件。它们重量轻、易于回收,并且保持与传统泵相同的高水平功能性。

● 品牌定制选项: 可定制的香水泵让品牌能够通过独特的设计脱颖而出。无论是颜色、饰面还是形状,可定制的泵都能让品牌创造出与其香水美学相符的独特身份。这种灵活性在竞争激烈的市场中尤为重要,因为品牌认知在消费者决策中起着关键作用。

● 增强耐用性,延长印刷寿命: 香水泵现在的设计考虑到了耐用性,提供较长的按压寿命,确保它们能够承受反复使用。这些泵经过精心设计,可以长期保持其性能,即使按压数千次后也能提供一致的喷雾质量。

香水泵的应用

香水泵广泛应用于各种香水产品,满足不同消费者的需求:

● 奢侈香水: 高端香水通常使用优质泵,提供精致的喷雾体验。这些泵通常采用卷边设计,以确保产品完整性,旨在增强香水的奢华感。

● 旅行装香水瓶: 微型泵是旅行装香水瓶的理想选择,既方便携带又不牺牲性能。这些泵通常采用螺旋式设计,便于重新填充和更换。

● 身体喷雾和大瓶香水: 香水泵也用于较大的瓶子,例如身体喷雾。这些泵的设计目的是每次按压时喷出更多的喷雾,确保快速、高效地使用。

● 化妆品行业整合: 除了香水,泵还用于各种化妆品,例如面部喷雾和发胶。它们的多功能性使其成为更广泛的美容行业中不可或缺的组成部分。

制造香水泵的挑战

制造香水泵面临多项挑战,制造商必须解决这些挑战才能确保始终如一的质量:

● 确保大批量生产的精度: 香水泵的零部件和组装需要高精度。在大批量生产中,保持这种精度可能具有挑战性,需要先进的制造技术 以及严格的质量控制措施。凭借全自动化生产线,WUBA 的月产量可达 1.5 亿件。

● 质量控制标准: 确保每个泵都完美运行至关重要。必须严格执行质量控制标准,每个泵都要接受喷雾一致性、耐用性和防漏测试。

● 环境法规与合规性: 随着可持续性成为主要关注点,制造商必须遵守有关香水泵所用材料的环境法规。这包括减少塑料废物、使用可回收材料以及尽量减少生产过程中的碳足迹。

结论

香水泵在提升整体香水体验方面发挥着关键作用,从提供精确的喷雾到通过可再填充设计提供可持续性。随着香水行业的不断发展,香水泵背后的技术也在不断发展。像 WUBA 这样的公司处于创新的前沿,提供满足消费者和环境需求的先进解决方案。WUBA 专注于精准、可持续性和定制,正在塑造香水包装的未来,以打造一个更加环保和奢华的世界。